|

| August 01, 2017 | Volume 13 Issue 29 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

Driving down automotive headlamp costs at Renault

By Paul-Henri Matha, Lighting Expert, Groupe Renault

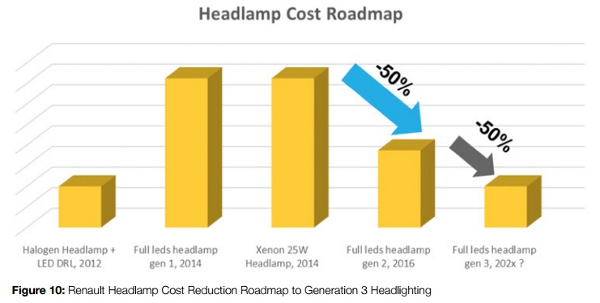

Automotive headlight design is an important part of the Renault brand these days and our ‘C shape' headlights are a signature part of the appeal of our cars. About 30% of the cost of automotive headlight assemblies can be found in the mechanics and 70% in the electronics. Hence, any savings that can be made on the electronic side will have a profound influence on the overall cost of these units. This article will outline how we have broken down our headlamp costs and used thermal analysis tools to incrementally optimize headlight designs to achieve a 50% cost reduction in the two years from 2014-2016 and how we intend to halve it again in the next few years.

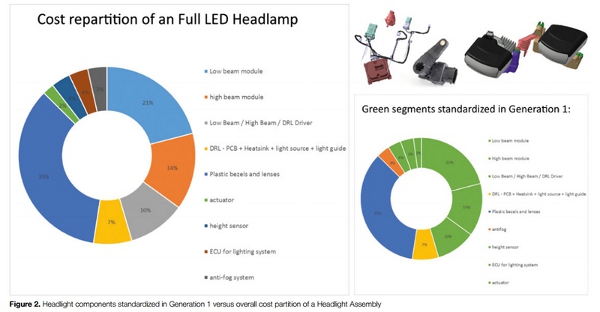

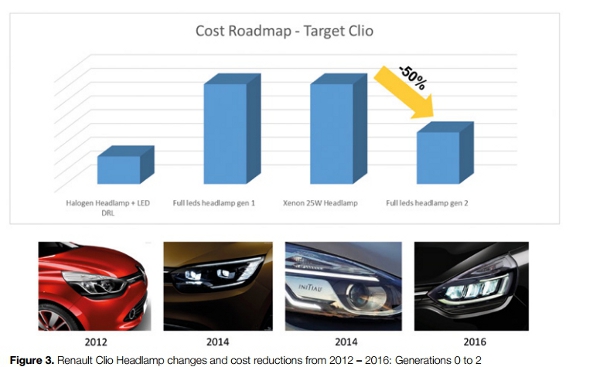

In Generation 1 of our full LED headlight assemblies we looked at six of our C and D-segment vehicles from the Espace to the Koleos. (Figure 1) We first standardized all platforms to one common height sensor, one common static leveller, one common DRL/low beam/high beam driver, one common central connector, and common low and high beam modules with two suppliers for each. We did this in one year by examining the partition of costs and standardized about 60% of the components of our headlights. (Figure 2) It can be seen that the plastics we used only made up about 30% of the overall assembly price. The volume effect is the main cost factor for a headlamp's part price as is its supply entry ticket. However, by moving from Halogen headlights in 2012 (see figure 3) to LED based headlights in 2014 the overall costs went up four-fold. This in itself gave us the impetus to see if we could cut costs in Generation 2 of our headlight evolution.

We focused our Generation 2 headlamp effort on our popular Segment B car, the Renault Clio, which was going through a A Driving down Automotive Headlamp costs at Renault By Paul-Henri Matha, Lighting Expert, Groupe Renault facelift and stylistically we wanted to move it to our LED based C-shape DRL lighting. (Figure 3) There were four pillars to our Generation 2 strategy:

- Be the first generalist automotive OEM with full LED headlights in this B-Segment car,

- To reduce by a factor of two the headlight part price between Generations 1 and 2,

- To have a better LED lighting performance than the Clio Initiale (which had Xenon 25W lights), and

- To reduce overall headlight assembly depth by 50mm.

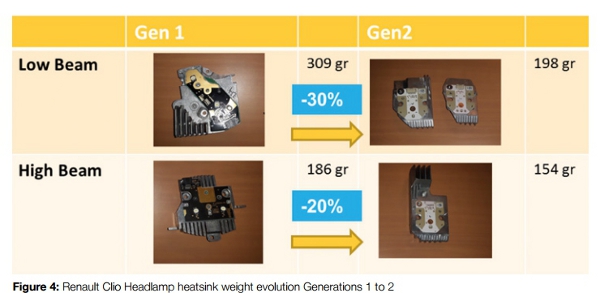

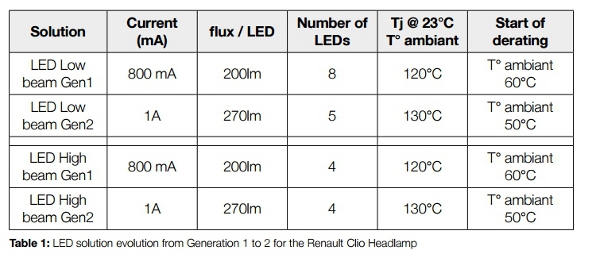

We standardized the Clio on a common LED Electronic Control Unit (ECU), a common height sensor, and a common leveller. We then focused on the LED Low Beam light and reduced its price to 30% by reducing the number of LEDs, the size of the heatsink by 30%, and improved the optical system. By doing all these things (see Table 1) we improved the LED light flux by 33%, and reduced the assembly from eight to five LEDs. We also increased optical efficiency by 25% and produced an overall assembly size reduction of 50mm. With the thermal improvements to the LEDs we were able to increase the LED current, increase the maximum junction temperature usage and the flux derating at a lower ambient temperature (Table 1). Similarly, with the associated heatsink design, we were able to get better junction temperature management and better derating management through our detailed thermal simulations. (Figure 4)

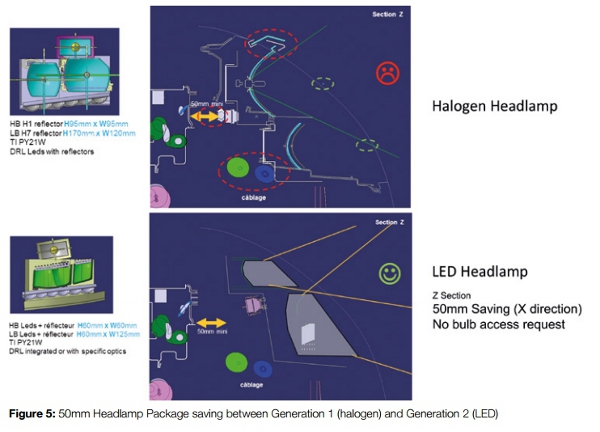

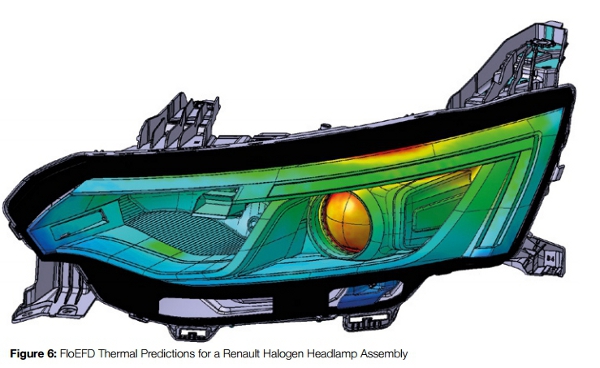

With respect to the overall headlamp package size, figure 5 shows the 50mm depth saving we were able to achieve between Generation 1 with a halogen headlamp and Generation 2 with a LED headlamp due to a better designed assembly. Figure 6 shows typical CFD simulations for a halogen headlamp in Mentor Graphics' CAD-embedded software, FloEFD®, illustrating the complex air flows and thermal effects to be found on the surfaces in the assembly.

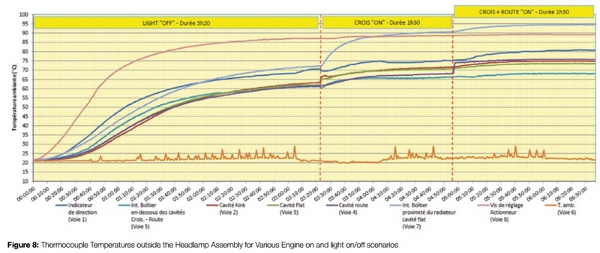

Looking deeper at our general CFD-based thermal analysis approach to headlamp design that typically is used to optimize designs, we would normally be interested in predicting lighting performance at 23°C outside the headlamp in ambient air and up to a maximum of 70°C for the outside temperature for the outer boundary of LED reliability. To validate our simulations, we therefore carried out some experimental tests where we fixed the ambient temperature outside the headlamp at 23°C and installed eight thermocouples outside the assembly (see figure 7) for a car with its engine on and off.

Figure 8 shows thermocouple time traces for both the engine on and car stationary for 3hr 30mins; then lights switched on for 1hr 30mins with the engine on and stationary, and then the lights on and engine driving for 1hr 30 minutes. It is clear that the temperatures can reach over 50°C inside the headlamp when the engine is idling and the lighting is on for a prolonged period. In addition, headlamp surface temperatures can rise to 65°C in certain idling conditions. With other tests we were able to show that with just a low beam on for an hour, the temperature inside the headlight went to 20°C and with both low and high beam on for an hour an extra 5°C in temperature was measured.

We also carried out a series of tests where we evaluated the effects of engine idling and lights either on or off by looking at Rjth of an Altilon LED with 3K/W and 3 chips @ 1A and for a Delta (Tjunction-Tcase) of 20°C. We were able to show that for ambient temperatures of 70°C and with both low beam and high beam lights on, together with the engine on that the junction temperature of the LEDs comes very close to the worst case scenario of 150°C. We concluded that it was not possible to design a LED system if we were to take into account all the use cases. The OEM must therefore define the best compromise. For example, at 23°C, after one hour engine idling, lighting performance was shown to be at 100%, but if the ambient temperature rose to 50°C for the same situation the lighting performance would go down to 80%. In order to respect this specification we concluded that a thermal sensor had to be added to the PCB so that the current could be reduced if the temperature at the LED was greater than a threshold we would define. We could then do a thermal derating and a flux derating of the full LED headlamp.

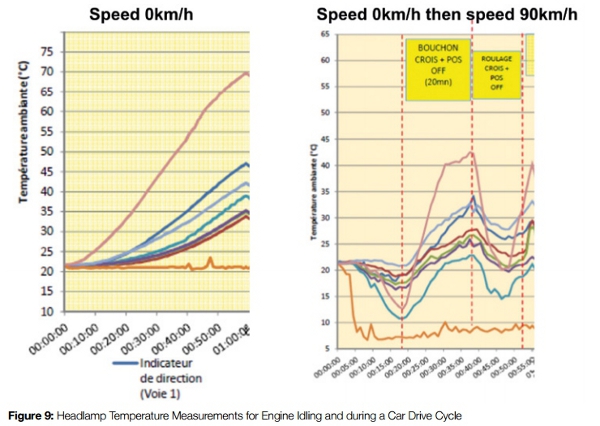

Going forward, we are putting in place an action plan to deal with simulation and testing of lighting in transient drive cycle modes. (Figure 9) As an OEM we want to be able to simulate the impact of car speed on its lighting's thermal performance, and in particular the thermal variation due to speed of each of our engines. This will make thermal CFD software key for lighting engineers in future.

We also need to be able to model the nearby engine bay's thermal behavior in parallel with the headlight simulation as they affect each other. And we also see the need for thermal management inside the headlamp when thermal inductors will be present. In short, Renault believes that the OEM should be responsible for the complete thermal system associated with headlamp design. To do so will make the OEM a market system leader.

Our immediate goal in the Renault Lighting Team with Generation 3 of our project is to increase the LED flux of headlamps from 270lm to 320lm by 2018-2020 and introduce new LED Drivers to deal with higher power, plus we are aiming for the introduction of Turn Indicators and AFS functionalities, as well as overall assembly size reduction. Finally, we are aiming for a Height Sensor regulation evolution. Our eventual target is to get our full headlamp assembly to reduce in price by another 50% bringing it to the levels we saw with halogen headlamps five years ago. (Figure 10)

Source: This article reposted in its entirety with full permissions from Mentor, a leader in electronic design automation.

Published August 2017

Rate this article

View our terms of use and privacy policy